TESTED

FOR THE UNEXPECTED

HALTI TEST LAB

When Juhani “Jussi” Hyökyvaara founded Halti in 1976, his goal was to create products that were not only thoroughly lab-tested but also proven in the real world. From the very beginning, our gear has been put to the test on expeditions and by world-class athletes. That mindset still drives us today: Innovate by listening to users. Test in real sports and real adventures. Learn from the experiences of professionals and enthusiasts alike. Improve—and then do it all over again.

How we test today

At Halti, we rigorously test both materials and finished products to make sure they perform in real-life conditions. Testing is built into every stage of product development—before, during, and after production.

MATERIAL TESTING BY LABORATORIES

All fabrics we use go through authorized lab tests conducted by our fabric suppliers and always aligned with Halti’s specific quality requirements. We test everything from knits and woven fabrics to waterproof materials, using tailored criteria for each.

What do we test for?

Waterproofness

Measured with a hydrostatic head test. Shows how many millimeters of water pressure the fabric can resist per square meter in 24 hours before leaking.

Breathability

Measured by water vapor transmission. Shows how many grams of moisture pass through the fabric per square meter in 24 hours.

Shrinkage

Evaluated after repeated washing and drying

Tear strength

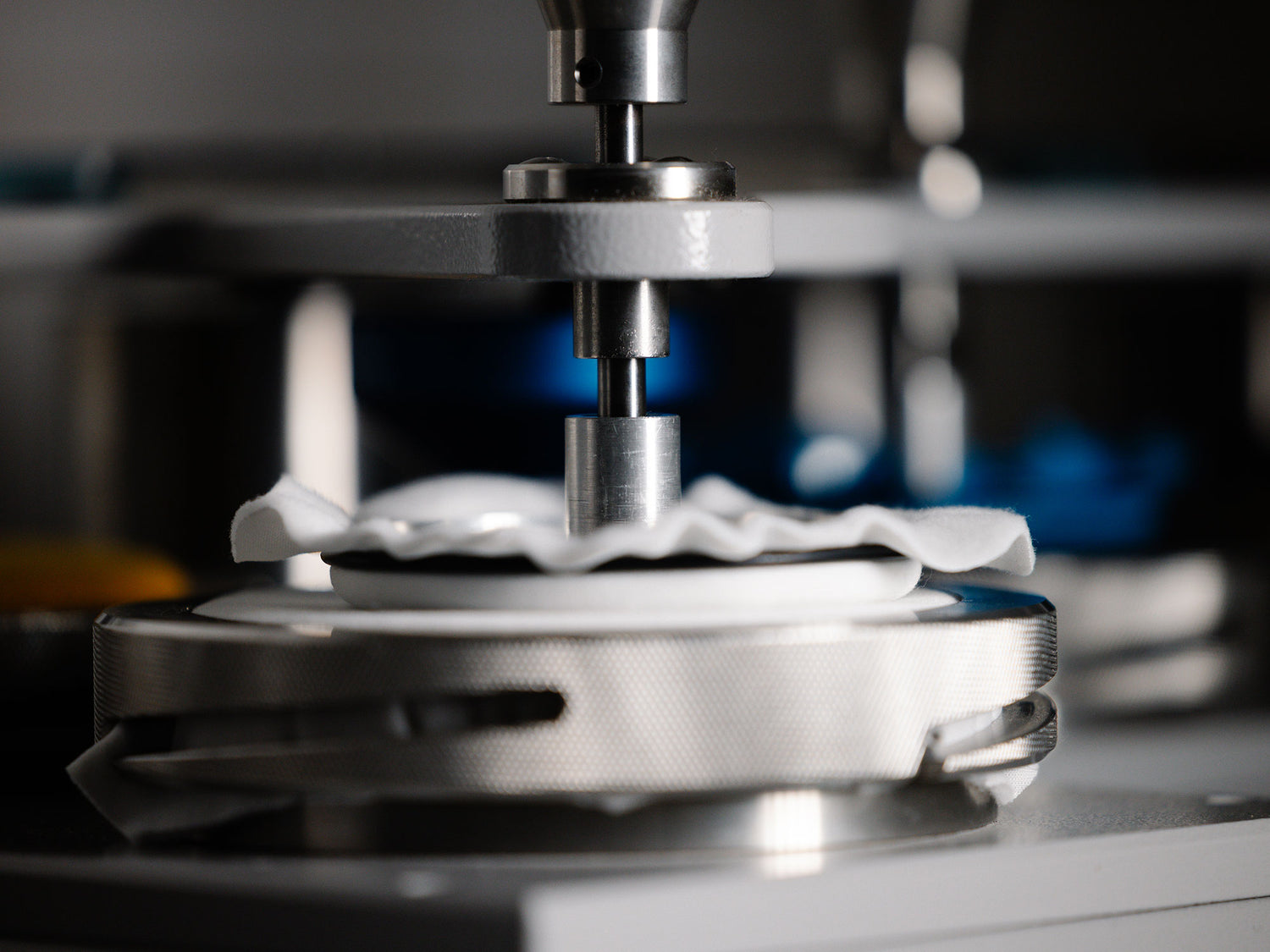

Measured with tensile testing equipment

Color fastness

Assessed by testing the fabric’s resistance to UV exposure and repeated washing.

DWR durability

Monitored by spray tests before wash and after repeated washing

Abrasion resistance

Martindale test for wear and pilling

UPF Rating

To test UV radiation transmittance of fabrics to assess their solar UV protective properties according to the standard EN 13758-1 +A1

Material composition

Includes weight and fiber content

Seam taping waterproofness

Measured with a hydrostatic head test

Print durability

Evaluated after repeated washing

When and where?

Material testing is done during the prototype, sample, and production stages. Tests are carried out in authorized laboratories, as well as at our garment factories and at our Headquarters in Finland. Our in-house product development runs our own internal testing for example for wash resistance, print durability, pilling resistance, and waterproofing (yes, sometimes by stepping into the shower with a shell)

What happens next?

Only materials with approved test results that meet our standards are accepted for production. If issues arise at any stage of testing, we adjust and improve early ensuring consistent quality in the final product.

PRODUCT TESTING BY PROS

Our product testing is done by athletes, professionals, and Halti staff members. The goal: test each product in the conditions and use it’s built for.